CASE HISTORY - VTC 1.5 ESTEC THERMAL CONTROL UNIT REFURBISHMENT

Challenge

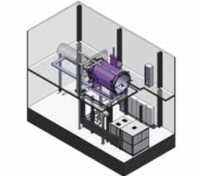

The ESA of Noordwijk, the European space and Technology Centre (ESTEC) is the centre of reference for satellite testing in Europe. It boasts a Large Space Simulator, a high vacuum facility with one of the largest solar simulators in the world. In order to increase the productivity of the ESTEC site, in 2009 ESA decided to modify an old vertical space simulator, of a diameter of a round 1.5 meters and a depth of 3, turning it into a horizontal one. To complete the facility with a smaller solar simulator. One of the aims of the project is to test components of the Bepi Colombo satellite, whose launch is planned for the year 2015 and for whose trajectory will bring it to pass within a very short distance from Mercury.

The simulation inside the VTC 1.5 envisages among the main characteristics:

The simulation inside the VTC 1.5 envisages among the main characteristics:

- High vacuum in the 10-7 mbar field

- Shroud temperature: ambient/-190°C in LN2 flooding mode

- Shroud temperature: -150/+150°C in pressurized GN2 circulation mode

- Solar simulator 15kW/m² over a target area of 0.5m², for a total of 7.5 kW dissipated energy

- Presence of three liquid cold plates in the field -60.... -125°

Other specific characteristics include the duration of the continuous 2000h test and the unattended mode-operating mode, with implications for the equipment reliability.

Solution

Solution

ATT's intervention consisted of creating the new shroud, a cold plate, the thermal control unit (LN2 and GN2) for the shroud and a thermoregulation control unit for the cold plate.

ATT was also responsible for the installation and testing of the system once it was totally integrated. The vessel, high vacuum system and solar simulation system were supplied by ESA, while ATT also handled the logistics of the vacuum system, since it is interconnected with the thermal part.

Angelantoni's space simulation expertise in all the functioning modes required by the specifications (flooding, pressurized GN2 circulation and indirect cooling systems) the high automation standard and the interface offered a more than exhaustive solution for the specification requirements, providing an added value of which ESA became wee aware.

Furthermore the reliability criteria applied by ATT, as well as the execution and subsequent sharing with ESA of the FMECA analysis of our system, ensured that the product quality was as expected in all its aspects.

Benefits

- In the presence of major thermal loads (up to 10kW) the flooding system supplied by ATT based on the communicating vessels principle generated considerable economic savings, as well as a great increase in reliability (eg the effect of one less LN2 pump on the FMECA analysis). The system functioned perfectly, also providing ATT with important indications useful for future projects.

- The capacity to guarantee high dissipative loads up to 15kW/m2 (even on limited shroud areas) backed by thermal-fluid dynamic analyses and appropriate implementation technologies for the shrouds.

- The supply of a shroud thermoregulation system functioning with both LN2 and GN2 (not simultaneously), sharing some of the components, guaranteed a considerable performance flexibility and high confidence in the final performance. The mastery of more than one thermoregulation strategy, while not being an innovation in the strict sense, enabled having a focus necessarily on a single technical solution.

Our strengths

- High expertise in the cryogenic systems, thanks to the vast experience acquired by ATT in the design and construction of thermal vacuum chambers since 1991.

- Innovative approach of the control and management solutions based on PLC automation and HMISW

- Flexibility and "problem solving" approach in all the project phases (design and engineering, installation, post - acceptance assistance)

Testimonial

"Last week we held the final acceptance review for the new thermal generator your company delivered to the Test Centre of the European Space Agency. Let me express my thanks to the Angelantoni team for their excellent work carried out under this contract. The performance of the delivered system fulfils all our expectations and we are convinced that it will have the opportunity to work again together in the future"

"Last week we held the final acceptance review for the new thermal generator your company delivered to the Test Centre of the European Space Agency. Let me express my thanks to the Angelantoni team for their excellent work carried out under this contract. The performance of the delivered system fulfils all our expectations and we are convinced that it will have the opportunity to work again together in the future"

Gaetan Piret, Head of ESTEC Test Centre Division - 1 November 2011