AN INNOVATIVE DESIGN FOR THE CLASSIFICATION OF HEATING UNITS

The residential building heating sector absorbs approximately 33% of the national energy requirements. Considering the global situation from the standpoint of both the environment and fuel costs, it has become necessary to study the behavior of heating plants and their components more in depth. In this respect, an important role is played by the optimization of the interaction between the terminal heating unit (or heat source) and the environment to be heated.

To achieve this aim, FONDITAL asked ANGELANTONI INDUSTRIE to implement the innovative design by Renzo Marchesi, engineer and Full Professor of Industrial Technical Physics at the Piacenza Campus of the Politecnico Institute of Milan. This design is based on the creation of a special Thermostatic Test Chamber for classifying the various terminal heating units.

The basis of comparison for such a classification is the energy supplied to the environment, thermal comfort being equal.

The basis of comparison for such a classification is the energy supplied to the environment, thermal comfort being equal.

For the reasons stated above, compared to the consolidated test methodologies, it became necessary to develop new systems that would permit a univocal evaluation of all the different types of terminal heating units.

The need to limit the energy used in home heating requires precise experimental measurements for the various conditions in which different terminal heating units are used.

The system developed in addition to providing accurate measurements in compliance with the European standard EN 442 enables the additional assessments necessary for determining more realistic evaluation indices for the different types of terminal heating units.

System description

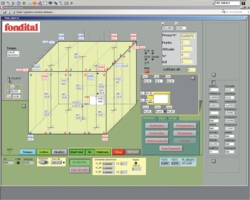

Thermostatic chamber and plant engineering for the control of the wall temperature

The structure consists of walls cooled by a cryogenic cooling fluid having the structural characteristics indicated in standard EN 442. This principle has already been used by Angelantoni Industrie for the famous preservation chamber for Ötzi, the Similaun mummy.

The structure consists of walls cooled by a cryogenic cooling fluid having the structural characteristics indicated in standard EN 442. This principle has already been used by Angelantoni Industrie for the famous preservation chamber for Ötzi, the Similaun mummy.- The central panels of the wall behind the heating unit (ref. EN 442) receive the fluid by means of an autonomous circuit permitting the simulation of cold surfaces.

- In order to guarantee greater accuracy in controlling the temperature, two cooling sources have been provided. The working temperature range is between -10°C and 40°C.

- A special device combined with a controlled and position able ventilation system makes it possible to evaluate the influence of the make-up air on the temperature distribution inside the thermostatic chamber and on the power exchanged.

- The temperature measurements are obtained through a mapping of different positions on the air and the walls.

- The mean radiant temperature is measured using special dedicated instruments.

- For other measurements - velocity and flow - at least two simultaneous measurement points and three flow meters are used.

Note: Using the configuration indicated, a great variety of plant thermal situations can be reproduced; these can be used to compare the energy performance of heating and cooling terminals.

Plant design for control of the heating unit temperature and flow rate

Different terminal heating units vary considerably in their heat transfer fluid flow rate requirements. A flow rate control system is necessary that can ensure a constant value.

Measurement instruments

Primary supply system

Primary supply system

For the primary system supplying the heat transfer fluid to the terminal heating unit, a thermostat control system is necessary to ensure that the temperature remains stable, with an accuracy of ±0.5°C.

Secondary supply system (chamber housing)

The housing of the test chamber is externally adiabatic, whereas it exchanges thermal energy with the internal air and directly by thermal radiation with the heating unit. For the purposes of a correct quantification of the phenomena, surface temperature must be accurately determined. The method envisages the measurement of the incoming and outgoing temperature of every panel, the verification of the surface uniformity, and a precise measurement.

Radiation measurement

Radiation measurement

The flow exchanged by radiation is of great importance as far as thermal comfort is concerned. Values must be measured with extreme accuracy. In addition to the surface temperatures, the operating temperature and measurement of the radiation are very important.

Thermal and thermo fluid dynamics fields

For the determination of the convective flow, a detailed knowledge of the thermal field and velocity field is necessary. An appropriate grid of sensors provides the essential information.